Advertisement: Created by TIAC Times in Partnership with Super Insulation, LLC.

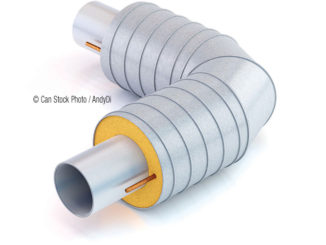

The rugged, waterproof insulation blanket for hot service applications helps address a problem that has been plaguing industrial facilities for decades—corrosion under insulation (CUI). Lewco Super Mat’s hydrophobic and other technical properties have earned its approval among global companies, including Cenovus and Suncor in Canada and ExxonMobil and Marathon in the United States. In fact, for more than 40 years now, world-class refineries have been proving that long-term hydrophobic insulation can be trusted to effectively manage the risk of CUI.

Monica Chauviere is a mechanical engineer, retired from a major oil company where she was a non-metallic materials SME. She is providing technical expertise to Super Insulation LLC, manufacturer of Lewco Super Mat. She says Super Mat’s properties and features have helped it gain widespread acceptance in many industrial applications.

“This concept of using hydrophobic insulation has been around since the mid-70s, and it’s well-proven that the two-pronged approach of eliminating long durations of water contact and assuring water is not held up behind insulation by improper equipment design is very effective in reducing the risk of CUI,” Chauviere says. “As a hydrophobic flexible blanket, Super Mat has several cost and schedule saving benefits, such as being hydrophobic to 315 degrees C (600 oF), unbreakable, and infinitely reusable.”

Although Super Mat shares the hydrophobic flexible blanket category with other materials, it is a completely unique product and serves as a no-dust alternative to aerogel-containing blanket products. It consists of only two constituent materials: E-glass needle-felted blanket and polytetrafluoroethylene (PTFE).

“The hydrophobic property comes from the surface tension of the water in contact with PTFE, rather than an added chemical hydrophobe,” Chauviere says. “Because there are no other constituents, Super Mat releases no particulate matter, hydrophobe or other additive as respirable dust.”

Being unbreakable and reusable is a large step toward reducing the cost of ownership. However, an additional aspect of cost avoidance is a sustained insulation value, allowed by Super Mat’s hydrophobic property.

“Insulation can’t do its job with water in it, and if it has water in it, the equipment is likely not performing well,” Chauviere says. “This is costing a company money in terms of wasted heat energy, inefficient operation, off-spec product, or increased risk of corrosion.

Additional cost savings stem from the four standard manufactured thicknesses of Super Mat, including 25 mm. This allows the ability to install fewer layers when three or more layers of standard thickness aerogel blanket are specified.

Understanding Super Mat technology hinges on grasping the full economic picture, including costs associated with underperforming equipment and CUI. “If a company only understands a tiny piece of the equation—the purchase and installation cost—they don’t understand the value of cost avoidance during the performance life of the equipment,” Chauviere says. “Reducing the risk of CUI, inefficient operations, and needless energy loss is really fairly simple. We believe helping facility owners understand the cause and effect related to thermal insulation allows them to make the wisest choices regarding their facility.”

Find out more about this new innovative industrial insulation at www.lewcosupermat.com and hpinsulation.ca. Email dslandro@hpinsulation.ca today to learn more about Super Mat.▪